Pioneers in Gold Recovery Solutions

For over five decades, Haycarb has been a global pioneer in coconut shell activated carbon for gold recovery, supplying some of the world’s most prominent mining operations with reliable, high-performance carbon solutions.

Our story began in the late 1970s, when Haycarb delivered its first major consignment of activated carbon to a gold mine in Nevada, a defining moment that marked our entry into the global mining supply chain This partnership came at a time when the gold mining industry was evolving towards safer CIP/CIL processes for gold extraction and over the decades, we have grown into a trusted gold mining carbon supplier in USA and in all major gold mining locations globally, supporting the industry’s transition towards more environmentally responsible extraction methods.

Over the decades, we have grown into a trusted sustainable activated carbon supplier for mining in the USA and across major gold-mining locations globally, supporting the industry’s transition toward environmentally responsible gold recovery technologies.

From that ground breaking milestone, Haycarb has dominated supply to the gold mining industry, built on a reputation of product innovation, supply reliability, quality consistency and a sustainable supply chain and manufacturing paradigm. Today, our high-efficiency gold adsorption carbon is trusted across continents helping mines maximize recovery efficiency, minimize gold loss in the circuit and meet environmental commitments.

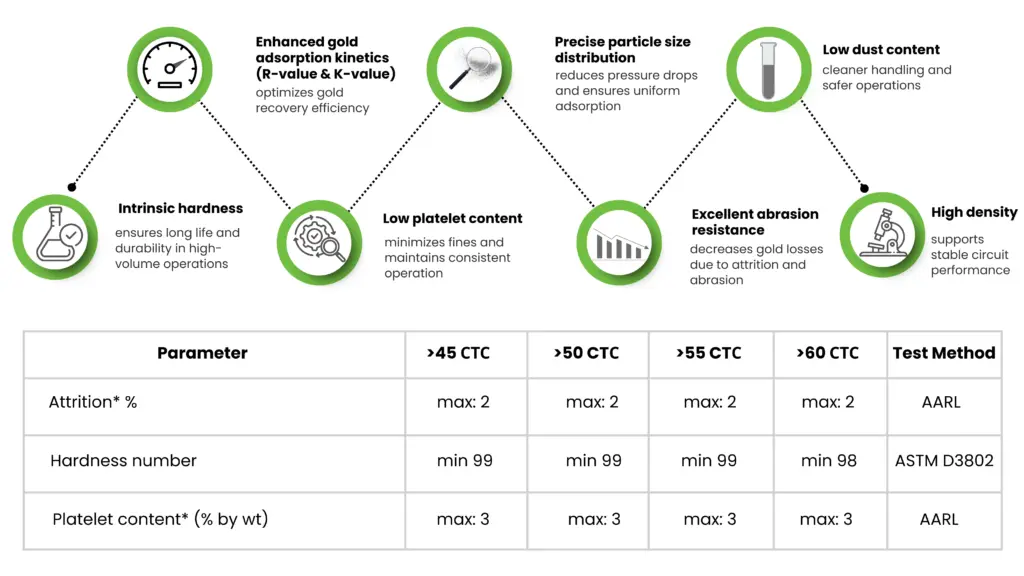

Key Product Features

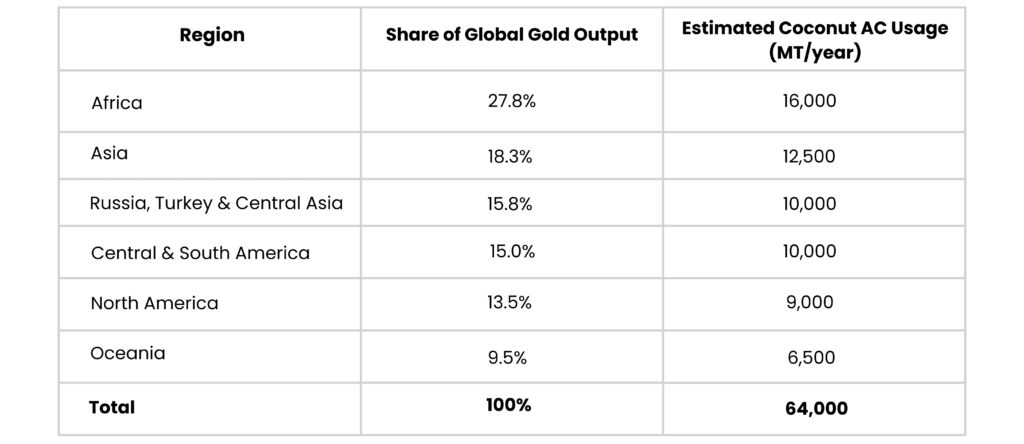

Gold Recovery Activated Carbon Market Outlook

The global Gold Recovery Activated Carbon market has demonstrated steady and sustained growth over the past decade, underpinned by rising gold prices and the increasing demand for efficient, sustainable gold recovery solutions.

From an application standpoint, Carbon-in-Leach (CIL) processes leads the market, representing the largest share of usage in gold recovery operations, followed by Carbon-in-Pulp (CIP) and Carbon-in-Column (CIC) systems. The widespread preference for CIL stems from its high efficiency, cost-effectiveness and adaptability to large-scale gold recovery circuits.

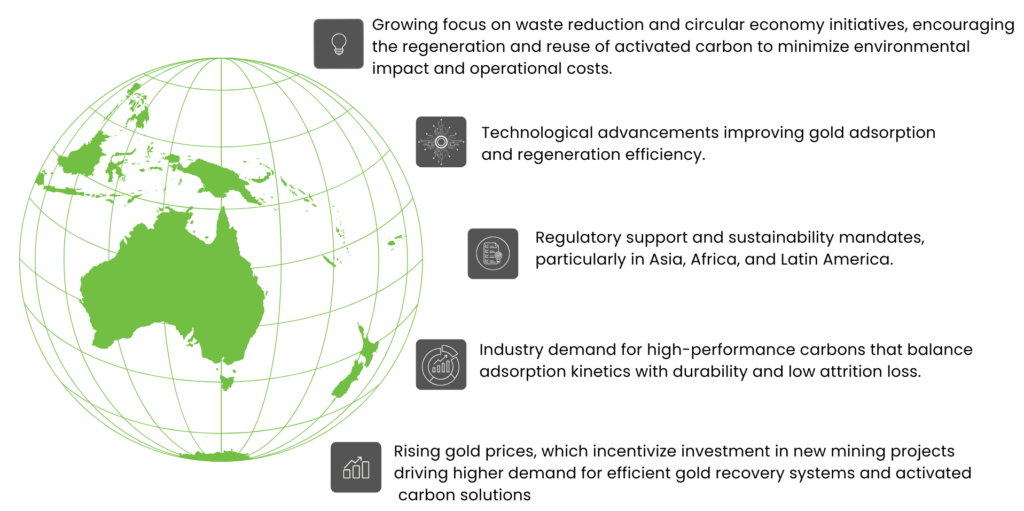

This market expansion is supported by broader global trends:

Supporting Africa’s Growing Gold Recovery Industry

Africa is now the world’s largest gold-producing region, contributing approximately 1,004 Metric tons of gold in 2023, or 27.8% of global production. For example, in Ghana, output was reported to have risen by ~19.3% in 2024, building on a strong 2023 base. Many West African mines are scaling up or transitioning from heap-leach to higher-throughput CIL/CIP circuits, driven by favorable gold prices and increased investment.

Reflecting this growth, Africa is also the largest global consumer of coconut shell–based activated carbon. Large-scale operations and small to medium scale artisanal mining in South Africa, Zimbabwe, DRC, Ghana, Mali, Burkina Faso, Tanzania and Sudan drive this demand highlighting the need for a reliable activated carbon supplier in Africa.

Therefore, Africa represents the largest incremental growth region for gold production, meaning carbon usage is expected to grow significantly as mining operations expand and modernize.

Empowering the Americans with Reliable Carbon Solutions

North and Latin America together account for approximately 19,000 Metric tons of coconut shell–based activated carbon per year, representing about 30% of global usage.

Recent reports indicate increases in smaller producer countries, with Latin American mines stepping up output volumes. For example, the “other producers” group recorded higher gold production in 2023, highlighting growth in emerging jurisdictions.

Latin America offers significant upside growth potential for gold recovery carbon, though the pace may be slower and less robust compared to Africa or Central Asia. Mining operations in the region are increasingly investing in higher-throughput CIP/CIL circuits, which will drive gradual increases in carbon demand.

Strengthening Australia’s Gold Mining Capabilities

Australia is one of the world’s most technically advanced and sustainability-focused gold-producing regions, with large-scale CIP/CIL plants requiring high-performance carbon for efficient gold recovery (World Gold Council, 2024).

Australia is one of the world’s most technically advanced and sustainability-focused gold-producing regions, with large-scale CIP/CIL plants requiring high-performance carbon for efficient gold recovery (World Gold Council, 2024).

Haycarb holds a commanding presence in the Australian gold recovery market, with approximately 60% market share, positioning us as the leading supplier of activated carbon to the region’s gold mining sector. We are proud to supply all the major global mining groups operating across Australia, delivering consistent, high-quality carbon solutions that power the country’s most advanced recovery facilities.

Our marketing offices, distributors, and strategically located stocks across major mining regions ensure seamless supply chain continuity and rapid technical support, enabling mines to maintain operational efficiency and performance stability.

The demand for gold recovery carbon in Australia operations continues to grow, driven by the industry’s focus on efficiency, durability, and environmentally responsible gold recovery technologies. For CIP/CIL operations, Australia’s advanced gold recovery facilities emphasize materials that ensure durability, efficient adsorption and consistent performance in both high-volume and heap-leach environments. These capabilities are further enhanced through improved carbon reactivation for mining circuits, supporting circular use and reducing operational costs.

Central & Far East Asia – Expanding Reach, Customized Solutions

The demand for gold recovery carbon in Asia, especially in Indonesia and Myanmar continues to rise as mining operations expand and processing technologies advance.

These diverse geological conditions highlight the need for adaptable carbon grades that support efficient adsorption and stable circuit performance in both emerging and established gold recovery facilities.

Turkey, Central Asia & Russia – Strategic Gold Production Amidst Geopolitical Shifts

Diverse Central Asian region and Russia, accounts for approximately 10,000 Metric tons of gold recovery carbon for CIP/CIL plants per year, representing 15.8% of global gold production.

In Russia, Polyus reported a ~7% increase in gold output in 2024, reaching 3 million ounces, boosted by high gold prices. Historical studies show that a significant proportion of global gold mine output growth over the past decades has come from both China and Russia. This reflects ongoing expansions and modernization of gold recovery circuits in the region.

Despite ongoing geopolitical shifts and related challenges, including sanctions and the need to source equipment from alternative suppliers, Russian mining operations continue to expand and modernize carbon-in-pulp gold extraction processes and carbon-in-leach adsorption systems, underscoring the region’s strategic importance in global gold production. This resilience highlights the region’s strategic importance in global gold production.

Central Asia is a key growth region where rising gold prices are driving higher production, which in turn translates to increased demand for high-efficiency coconut shell–based activated carbon in CIP/CIL operations.

North America – Advanced Gold Recovery Operations

Canada remains a highly developed and technologically advanced gold-producing region, with major mining operations concentrated in provinces such as Ontario, Quebec, and British Columbia. Prominent mines, including Hemlo and Côté Gold, play a critical role in sustaining national output and maintaining the country’s reputation as a stable supplier of high-quality gold.

The North American gold mining sector is characterized by well-established, mature operations that focus on optimizing efficiency, maximizing recovery, and adopting modern gold extraction technologies. These mines typically operate at high capacity with established processing circuits, which translates to steady but relatively slower growth in carbon demand compared to emerging regions like Africa or Central Asia, where rapid expansion and new projects are driving higher consumption.

While growth in carbon demand may be modest, North American operations continue to prioritize consistent quality, process optimization, and environmental compliance, ensuring reliable gold recovery and stable long-term performance for activated carbon suppliers.

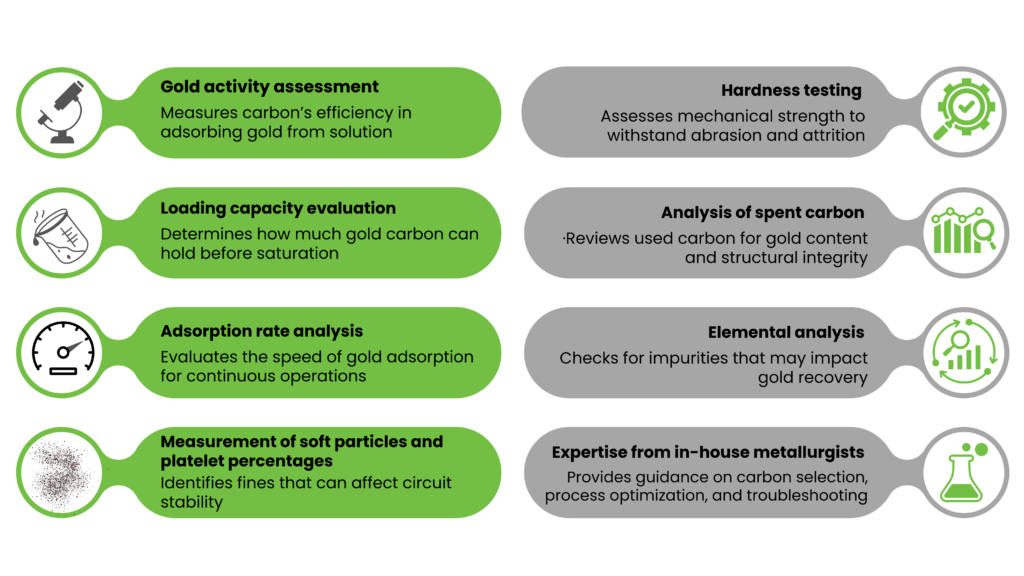

Comprehensive Testing and Process Optimization

With world-class testing facilities and a team of expert metallurgists, Haycarb delivers precise analytical insights that help mining operations achieve higher gold recovery efficiency and longer carbon service life. Every carbon batch is rigorously tested under simulated process conditions to guarantee superior performance, including:

Sustainability Commitment – Haycarb Roadmap 2030

Sustainability lies at the core of Haycarb’s mission.

We manufacture all our carbons using renewable coconut shells, leveraging low-emission, energy-efficient technologies to minimize our carbon footprint.

Through our roadmap 2030 sustainability framework, we aim to achieve carbon-neutral manufacturing, circular reactivation processes, and reduced waste generation across all facilities.

Certified under ISO 9001:2008 and ISO 14001:2015, Haycarb continues to uphold the highest standards in quality, safety, and environmental responsibility.

Delivering Purity, Performance, and Purpose

From the gold belts of Africa to the high-tech mines of Australia and the Americas, Haycarb continues to define the global standard in activated carbon for gold recovery. With strategically positioned distribution networks and technical collaborations across continents, Haycarb ensures reliable supply continuity, consistent product quality, and responsive local support. This global partnership approach enables mining operations of every scale to achieve stable circuit performance and maximize gold yield, while contributing to a more sustainable future for the industry.

With innovation at our core and sustainability as our compass, we power gold recovery across continents delivering purity, performance, and purpose to every mining partner we serve.

Refer to our attached brochure for more information:

FAQs

- What type of activated carbon is most effective for gold recovery?

Coconut shell–based activated carbon is widely considered the most efficient for gold recovery due to its high hardness, microporous structure, and strong adsorption capacity. It also offers renewable sourcing advantages compared to coal- or wood-based carbons.

- How does activated carbon contribute to the gold recovery process?

Activated carbon plays a key role in Carbon-in-Pulp (CIP), Carbon-in-Leach (CIL), and Carbon-in-Column (CIC) systems by adsorbing dissolved gold from cyanide leach solutions. Its surface area and pore structure directly affect recovery efficiency and gold yield.

- Which regions show the highest demand for gold recovery carbon globally?

Regions such as Africa, Central Asia and Russia are seeing the fastest growth in demand for gold recovery carbon, driven by expanding gold mining operations, process modernization, and stricter sustainability standards.

- What factors determine the efficiency of activated carbon in CIP/CIL gold recovery systems?

Efficiency depends on factors such as particle size distribution, hardness, pore structure, and adsorption kinetics. Proper process control and regular carbon reactivation also play a vital role in maintaining consistent recovery performance.

- Why is the Asia-Pacific region becoming a major hub for gold recovery carbon demand?

Oceana, led by Australia, China, and Southeast Asian countries, is witnessing a surge in mining activity and modernization of gold processing facilities and emerging of small to medium scale mining operations. This growth fuels demand for advanced carbon grades that can deliver both efficiency and environmental compliance by using CIL circuits.