Introduction

Haycarb has long been recognized for delivering specialized industrial activated carbon filtration solutions that ensure excellence in water treatment and purification. Among our core offerings is specialized Activated Carbon for dechlorination in beverage water treatment, engineered to effectively remove residual disinfectant agents generated by chlorine gas, sodium hypochlorite (NaOCl), and calcium hypochlorite [Ca(OCl)₂]. These carbons are specifically designed to adsorb raw water containing organic compounds (VOCs) and residual contaminants responsible for undesirable taste and odor, thereby enhancing overall water quality.

In water treatment applications, two primary grades of activated carbon are widely used:

• Standard Carbon – optimized for de-chlorination and removal of free chlorine.

• Catalytic Carbon – designed for the more complex removal of chloramine species.

For one of the largest beverage producers in Europe, Haycarb supplied a standard Activated Carbon grade PHO 14×45 AW for de-chlorination carbon to meet chlorine removal requirements, as part of their comprehensive approach to drinking water treatment.

Problem Identification

The customer had been facing performance limitations with their previous activated carbon supplier and decided to switch to Haycarb. Following successful laboratory-scale validation of our PHO 14×45 AW grade, they proceeded with a commercial order for use in their large-scale carbon filtration system.

During the initial filter operation, however, the customer observed excessive dust generation from the new carbon. This resulted in an increased pressure drop across the system and had an adverse impact on treated water clarity and quality.

Root Causes Identified:

1. Abrasion of Carbon by Pump Impeller

- The client had used a submersible pump to feed PHO 14×45 AW into the filter. This method forced carbon particles through the rotating impeller, causing attrition and breakdown into fine dust. The effect was more pronounced during continuous operation cycles, making the feeding method a significant contributor to carbon attrition & dust generation.

2. Improper Backwashing Conditions

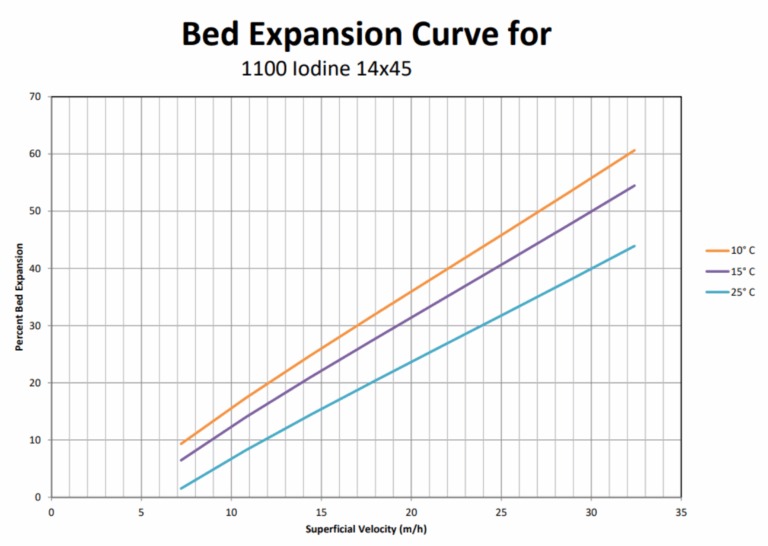

- The backwashing process, designed to clean the filter media by reversing water flow, was not optimized for Haycarb’s carbon. The client applied the same backwash flow rate used for pellet carbon, which has larger particle size and higher bulk density. For PHO 14×45 AW, with its lower bulk density and smaller particle size, this excessive flow expanded the bed by nearly 50%. The resulting turbulence accelerated attrition and dust release. For optimal operation, backwashing optimization for carbon filters requires bed expansion to be maintained at around 30%.

3. System Configuration Mismatch

- Critical operating parameters including linear velocity, pump design, and backwash settings had been calibrated for the previous supplier’s carbon. Since Haycarb’s PHO 14×45 AW has different bulk density and hydraulic characteristics, these parameters were not fully aligned. This mismatch led to system instability and dust formation until corrective adjustments were made.

Solutions Implemented

Haycarb’s technical team carried out a site audit and implemented the following corrective measures:

Adjusted Linear Velocity

- Reduced linear velocity to achieve 30% bed expansion, enabling effective cleaning without excessive shear stress.

Optimized Bed Expansion Parameters

- Introduced bed expansion graphs tailored to the density and physical properties of PHO 14×45 AW, ensuring uniform backwashing while minimizing carbon breakage.

Enhanced Backwashing Procedures

- Standardized flow rates, duration, and frequency of backwash cycles, significantly reducing dust generation.

Sterilization Practices

- Recommended periodic sterilization protocols to prevent microbial growth, safeguarding against filter fouling and performance losses.

As a result of these adjustments, system efficiency and carbon stability were restored, leading to improved water quality and customer satisfaction.

General Recommendations

This case highlights the importance of aligning operational parameters with the physical and hydraulic characteristics of the activated carbon in use. For similar applications, Haycarb’s experts recommend:

1. Comprehensive System Assessment

- Evaluate source water chemistry, system hydraulics, and pump design prior to carbon replacement.

2. Appropriate Carbon Selection

- Choose between standard and catalytic carbons depending on whether the target contaminant is free chlorine or chloramine.

3. Optimized Operational Settings

- Match linear velocity, bed expansion height, and pump configuration with the density and mechanical properties of the carbon.

4. Preventive Maintenance & Sterilization

- Implement sterilization protocols to prevent biofouling, and schedule periodic monitoring and backwash adjustments to maintain long-term carbon integrity.

Partner with Haycarb Today

Please fill in the required information and our team will be happy to help you find the right solutions.