Invisible to the eye yet persistent in the environment, PFAS, often referred to as “forever chemicals”—have emerged as one of the most complex challenges in modern water treatment. Found in drinking water sources worldwide, these compounds resist natural degradation, allowing them to accumulate over time and pose serious risks to human health and ecosystems. As a result, advanced PFAS adsorption water treatment systems using Activated Carbon for PFAS Removal are increasingly essential for protecting drinking water quality.

Recent studies have detected PFAS contamination in a significant proportion of global water sources, including groundwater and surface water near industrial zones and landfills. Even at trace levels, PFAS exposure has been linked to immune suppression, hormonal disruption, liver toxicity, and certain cancers. In response, regulatory bodies such as the U.S. Environmental Protection Agency (EPA), the European Food Safety Authority (EFSA), and other global authorities have tightened permissible limits, driving demand for PFAS-compliant drinking water filtration solutions that are capable of delivering consistent, long-term performance.

Advanced Engineering for Superior Adsorption

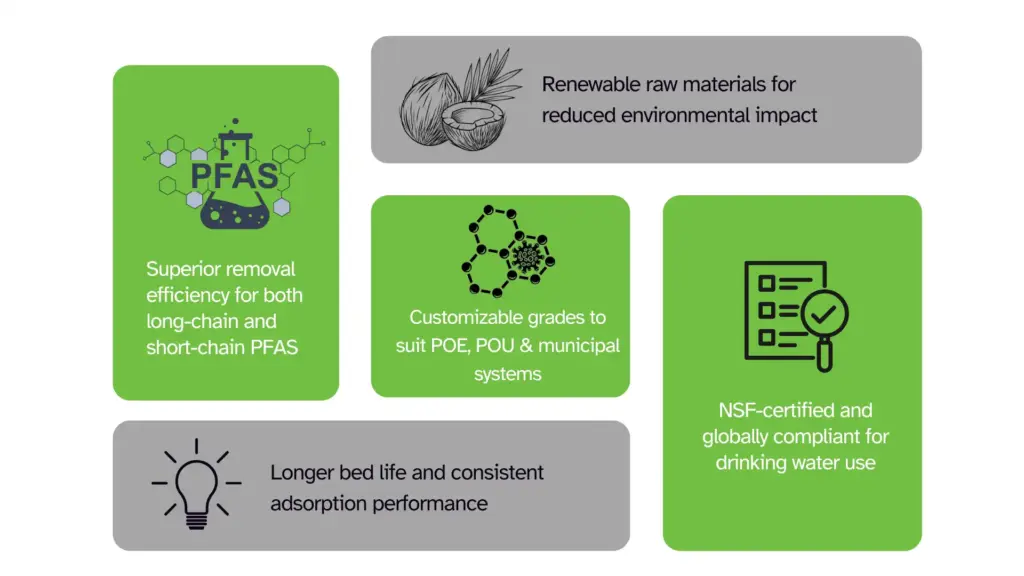

Unlike traditional bituminous coal-based carbons, Haycarb’s PFAS 5000 Series is produced from renewable coconut shell and wood-based raw materials. Engineered specifically as activated carbon for PFAS removal, these materials offer exceptionally high micropore volume and surface areas exceeding 1,000 m²/g, making them a high micropore activated carbon for PFAS removal.

This highly engineered pore structure enhances contact efficiency, resulting in longer bed life and more stable performance, even in high-throughput treatment systems. Haycarb’s Granular Activated Carbon (GAC) for PFAS treatment has been specifically optimised for PFAS removal, making it one of the industry’s most trusted granular activated carbon solutions for PFAS treatment.

Independent laboratory testing has demonstrated over 99% removal efficiency for key long-chain PFAS compounds such as PFOA and PFOS, while also delivering strong performance against short-chain PFAS, which are typically more challenging to remove. In pilot-scale testing, the PFAS 5000 Series achieved breakthrough points up to 40% higher than conventional coal-based carbons, underscoring its durability and adsorption endurance under continuous operation.

For large-scale systems, Haycarb’s carbon grades maintain stable performance in municipal PFAS water treatment solutions, even under variable flow rates and high contaminant loads.

Certified Safety and Proven Versatility

The PFAS 5000 Series is NSF-certified and compliant with global drinking water standards, ensuring suitability for municipal, Point-of-Entry (POE), and Point-of-Use (POU) filtration systems. In addition, Haycarb aligns its PFAS treatment solutions with Water Quality Association (WQA) guidelines and best practices, reinforcing confidence in performance, material safety, and application suitability across drinking water treatment systems.

Available in multiple particle sizes and iodine values ranging from 1000 to 1300, the product range can be tailored to diverse treatment requirements. Uniform activation ensures stable adsorption rates, minimal pressure drop, and reduced risk of operational challenges such as channeling or floating.

When deployed in municipal systems, the PFAS 5000 Series integrates seamlessly into GAC bed configurations, offering a scalable and practical pathway to compliance with evolving PFAS regulations.

How does Coconut Shell Activated Carbon Excel in PFAS Removal?

The secret to the PFAS 5000 Series’ outstanding performance lies in Haycarb’s decades of expertise in activated carbon science. Coconut shell activated carbon, known for its dense pore structure and hardness, delivers higher adsorption affinity for PFAS molecules compared to coal-based alternatives.

The superior microporosity distribution enhances the adsorption of smaller and short-chain PFAS compounds, a domain where many traditional GAC materials fall short. In comparative studies, Haycarb’s PFAS 5000 outperformed bituminous coal carbons by up to 35% in total PFAS removal efficiency, while offering longer operational life and reduced frequency of regeneration or replacement.

Furthermore, the use of renewable coconut shells the use of renewable coconut shells supports sustainable activated carbon for PFAS remediation, combining environmental responsibility with consistent product quality. This technical advantage, combined with Haycarb’s global manufacturing consistency and strict quality control, provides customers with unmatched reliability in performance and sustainability.

Sustainability without Compromise

Sustainability is central to the PFAS 5000 Series. Manufactured entirely from renewable raw materials, the product aligns with Haycarb’s “ACTIVATE” ESG Roadmap 2030, supporting environmental stewardship, resource efficiency, and emissions reduction while delivering high-performance PFAS adsorption media without compromising treatment efficiency.

Energy-efficient manufacturing processes and optimised reactivation systems further minimise environmental impact, allowing utilities and industries to achieve regulatory compliance without compromising sustainability goals.

Why Choose Haycarb’s PFAS 5000 Series?

A Smarter, Sustainable Path to PFAS-Free Water

With decades of expertise in activated carbon innovation, Haycarb continues to lead the evolution of sustainable water purification technologies. The PFAS 5000 Series represents a powerful combination of advanced material science, rigorous testing, and environmental responsibility, enabling communities, industries, and utilities to meet today’s PFAS challenges with confidence and build a safer, cleaner future for water treatment.

Frequently Asked Questions (FAQs)

- Why are PFAS considered more challenging to remove than other water contaminants? PFAS molecules are chemically stable and resistant to natural degradation due to their strong carbon–fluorine bonds. This makes them persist in water systems for decades. Unlike many organic contaminants, PFAS do not break down easily through conventional treatment methods, requiring advanced adsorption technologies with highly engineered pore structures and long contact times to achieve effective removal.

- How does activated carbon remove PFAS from water? Activated carbon removes PFAS primarily through adsorption, where PFAS molecules attach to the internal pore surfaces of the carbon. The effectiveness of this process depends on factors such as micropore volume, surface area, pore accessibility, and contact time. High-quality granular activated carbon enables stronger PFAS affinity, slower breakthrough, and more stable long-term performance in treatment systems.

- Why is coconut shell–based activated carbon more effective for PFAS removal than coal-based carbon? Coconut shell–based activated carbon has a denser and more uniform micropore structure compared to coal-based alternatives. This makes it particularly effective at adsorbing smaller and short-chain PFAS compounds, which are often the most difficult to remove. In addition, its higher hardness and lower attrition contribute to longer bed life, reduced replacement frequency, and more consistent treatment performance.

- How does PFAS regulation impact the design of water treatment systems? As PFAS limits continue to tighten globally treatment systems must be designed for higher adsorption efficiency, longer bed life, and predictable breakthrough behaviour. This places greater emphasis on selecting application-specific activated carbon, optimising GAC bed configurations, and ensuring performance validation through testing and certification.

- What should utilities and industries consider when selecting a PFAS treatment solution? Key considerations include PFAS removal efficiency, long-term performance, regulatory compliance, operational reliability, and the sustainability of the treatment media.